CC-Link IE Field is a high-speed, deterministic industrial Ethernet network designed for seamless communication between automation devices. While its performance is undeniable, power consumption can be a significant concern, especially in large-scale deployments. This article explores various techniques and strategies for minimizing the power footprint of CC-Link IE Field installations, leading to lower operational costs and improved energy efficiency. We will delve into hardware considerations, software optimizations, and network design principles that contribute to a greener and more sustainable industrial automation environment.

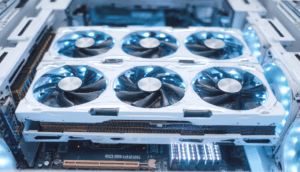

One crucial aspect of power reduction involves selecting appropriate hardware components. This includes choosing energy-efficient CC-Link IE Field modules, PLCs, and other network devices. Look for components with low-power chipsets and advanced power management features like sleep modes and dynamic voltage scaling. Additionally, consider the cabling infrastructure. Using shorter cable lengths and high-quality shielded cables minimizes signal attenuation, reducing the need for higher transmission power. Regularly inspect cable connections for any signs of corrosion or damage, as these can lead to increased resistance and higher power consumption. Furthermore, implementing Power over Ethernet (PoE) where applicable can consolidate power and data transmission, leading to infrastructure simplification and potential energy savings.

Software optimization plays a vital role in minimizing power usage. Efficient programming practices can significantly reduce the processing load on connected devices. For example, optimize data communication protocols to minimize the amount of data transmitted over the network. Implement data compression techniques where possible to reduce the bandwidth requirements and the associated processing power. Scheduled data transfers, rather than continuous polling, can also reduce the power consumption of slave devices. Furthermore, ensure that the software is regularly updated with the latest firmware and drivers, as these often include power-saving enhancements. Proper configuration of network parameters, such as the transmission speed and packet size, can also optimize network efficiency and minimize power consumption.

Network design is another critical factor in power management. Implementing a star topology, where devices connect directly to a central hub or switch, can minimize the number of hops and the overall network latency, leading to lower power consumption. Segmenting the network into smaller subnets can also reduce the broadcast traffic and the processing load on individual devices. Virtual LANs (VLANs) can isolate traffic and further optimize network performance. When designing the network layout, consider the physical proximity of devices. Grouping devices that frequently communicate with each other closer together can reduce cable lengths and signal attenuation. Proper grounding and shielding are also essential to prevent electromagnetic interference (EMI), which can lead to increased power consumption and data errors.

Finally, monitoring and analysis are crucial for identifying and addressing power consumption issues. Implement a network monitoring system to track the power usage of individual devices and the overall network. This data can be used to identify areas where power consumption is higher than expected and to implement corrective actions. Regular audits of the network configuration and hardware components can also help identify potential issues. By proactively monitoring and managing power consumption, you can ensure that your CC-Link IE Field network operates efficiently and sustainably. Continuous improvement and adaptation to new technologies are essential for maximizing energy efficiency in the long term.