In today’s rapidly evolving industrial landscape, the demand for reliable and high-performance data communication cables is paramount. These cables serve as the backbone of modern automation systems, enabling seamless data transfer and control across diverse applications. From factory floors and processing plants to healthcare facilities and research laboratories, industrial data communication cables play a crucial role in ensuring operational efficiency, safety, and productivity. The advent of Industry 4.0 and the Internet of Things (IoT) has further amplified the importance of these cables, as they facilitate the real-time exchange of data between machines, sensors, and control systems, driving intelligent decision-making and optimized performance.

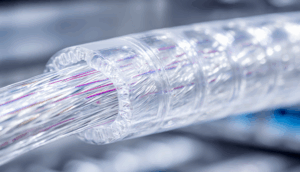

Selecting the appropriate industrial data communication cable requires careful consideration of several factors, including the application environment, data transmission requirements, and potential interference sources. Environmental conditions, such as temperature extremes, exposure to chemicals, and mechanical stress, can significantly impact cable performance and longevity. Factors like bandwidth, data rate, and signal integrity must also be taken into account to ensure reliable data transmission. Moreover, proper shielding and grounding techniques are essential to mitigate electromagnetic interference (EMI) and radio frequency interference (RFI), which can disrupt data flow and compromise system integrity. Common cable types include Ethernet cables (Cat5e, Cat6, Cat6a), Profibus cables, Profinet cables, and serial communication cables (RS-232, RS-485). Each cable type offers distinct performance characteristics and is suited for specific applications.

Beyond the technical specifications, adherence to industry standards and certifications is crucial for ensuring cable quality and compliance. Organizations like UL, CSA, and IEC have established rigorous testing and certification programs that validate cable performance and safety. Choosing certified cables provides assurance that they meet or exceed industry standards, minimizing the risk of failures and maximizing system reliability. Furthermore, proper installation and maintenance practices are essential for extending the lifespan of industrial data communication cables. This includes using appropriate connectors, avoiding excessive bending or twisting, and regularly inspecting cables for signs of damage or wear.

In the medical field, data communication cables play a vital role in connecting diagnostic equipment, patient monitoring systems, and medical imaging devices. The reliability and accuracy of these cables are of utmost importance, as they directly impact patient care and safety. Medical-grade cables are typically designed with enhanced shielding and sterilization capabilities to minimize interference and prevent the spread of infection. These cables must also comply with stringent regulatory requirements, such as those outlined by the FDA and other healthcare organizations.

The future of industrial data communication cables is driven by the increasing demand for higher bandwidth, faster data rates, and greater reliability. Emerging technologies like single-pair Ethernet (SPE) are poised to revolutionize industrial networking, offering a cost-effective and space-saving solution for connecting sensors and actuators. Wireless communication technologies, such as Wi-Fi 6 and 5G, are also gaining traction in industrial applications, providing flexibility and mobility. However, wired connections remain critical for applications requiring high bandwidth and deterministic performance. As industries continue to embrace digitalization and automation, industrial data communication cables will remain an indispensable component of the intelligent infrastructure, enabling seamless connectivity and driving innovation across diverse sectors.