The industrial and medical sectors are on the cusp of a transformative period, driven by advancements in data communication cable technology. As we approach 2025, several key innovations promise to enhance efficiency, reliability, and performance across a wide range of applications. This article delves into the specific breakthroughs poised to reshape these critical industries, exploring the underlying technologies and their potential impact.

One of the most significant advancements is the development of enhanced shielding techniques. Industrial environments are often rife with electromagnetic interference (EMI), which can severely degrade signal integrity. New cable designs incorporate multi-layered shielding, utilizing advanced materials and geometries to effectively block out external noise. This ensures reliable data transmission even in the most challenging electromagnetic environments. Furthermore, improved grounding methods are being implemented to minimize ground loops and further reduce noise susceptibility.

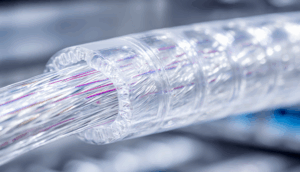

Another critical area of innovation is the development of cables with increased bandwidth and data transmission speeds. Modern industrial processes require the rapid transfer of vast amounts of data, especially with the rise of the Industrial Internet of Things (IIoT). New cable designs are leveraging advanced materials and manufacturing techniques to minimize signal attenuation and maximize bandwidth. This enables the seamless transmission of high-resolution video, sensor data, and control signals, facilitating real-time monitoring and control of industrial processes. Moreover, advancements in connector technology are ensuring robust and reliable connections, even under harsh environmental conditions.

The medical sector is also benefiting from these advancements. Medical imaging equipment, such as MRI scanners and CT scanners, requires cables capable of transmitting extremely high-resolution images with minimal distortion. New cable designs are being developed specifically for these applications, incorporating features such as low-noise construction and high-purity conductors. These cables enable clearer and more accurate images, leading to improved diagnostics and treatment outcomes. Furthermore, cables used in patient monitoring systems are becoming more reliable and resistant to interference, ensuring accurate and continuous data collection. The development of biocompatible cable materials is also a key focus, minimizing the risk of adverse reactions when cables come into contact with patients.

Finally, the durability and longevity of industrial and medical cables are being significantly improved. These sectors require cables that can withstand extreme temperatures, harsh chemicals, and constant flexing. New cable designs are incorporating advanced polymer materials and robust construction techniques to enhance their resistance to these environmental factors. This reduces the need for frequent cable replacements, minimizing downtime and lowering maintenance costs. Predictive maintenance technologies, coupled with smart cable monitoring systems, are also being developed to proactively identify potential cable failures, allowing for timely intervention and preventing costly disruptions. The future of industrial and medical cables is bright, with continuous innovation driving improved performance, reliability, and durability across a wide range of applications.