In today’s rapidly evolving industrial landscape, the demand for reliable and high-performance data communication cables is paramount. These cables form the backbone of critical infrastructure, facilitating seamless data transfer between various industrial devices, control systems, and networks. Unlike standard commercial cables, industrial data communication cables are engineered to withstand harsh environments, extreme temperatures, electromagnetic interference (EMI), and physical stress. This robustness is crucial for maintaining operational efficiency and preventing costly downtime.

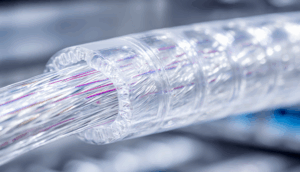

Several factors contribute to the superior performance of industrial data communication cables. Firstly, the choice of materials is crucial. Cables designed for harsh environments often utilize specialized polymers like fluoropolymers or polyurethane for insulation and jacketing. These materials offer excellent resistance to chemicals, abrasion, and UV radiation. Secondly, shielding plays a vital role in mitigating EMI, which is prevalent in industrial settings due to the presence of motors, transformers, and other electrical equipment. Braided copper shielding, aluminum foil shielding, or a combination of both are commonly employed to ensure signal integrity. Thirdly, robust construction techniques, such as stranding conductors for flexibility and employing strong jacketing materials, enhance the cable’s ability to withstand physical stress, bending, and vibration.

Within the realm of industrial data communication, several cable types cater to specific applications. Ethernet cables, complying with standards like Cat5e, Cat6, and Cat6a, are widely used for connecting devices in industrial Ethernet networks. These cables support high data rates and are essential for applications like programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial computers. Fieldbus cables, adhering to protocols like PROFIBUS, DeviceNet, and CANbus, are designed for connecting sensors, actuators, and other field devices to control systems. These cables typically feature twisted-pair construction and shielding to ensure reliable communication in noisy environments. Coaxial cables, offering excellent bandwidth and signal integrity, are used for applications like video surveillance and high-speed data transmission over longer distances.

Beyond material selection and cable type, proper installation and maintenance are essential for maximizing the lifespan and performance of industrial data communication cables. Cables should be installed according to manufacturer recommendations, avoiding sharp bends and excessive tension. Cable routing should be carefully planned to minimize exposure to harsh environments and potential sources of interference. Regular inspection of cables for damage, abrasion, and corrosion is crucial for identifying potential problems before they lead to failures. Proper grounding and bonding techniques are also essential for minimizing EMI and ensuring electrical safety.

In conclusion, industrial data communication cables are critical components of modern industrial infrastructure. Their robust design, specialized materials, and adherence to industry standards ensure reliable data transfer in demanding environments. Choosing the right cable for the application, coupled with proper installation and maintenance practices, is essential for maximizing performance and minimizing downtime, ultimately contributing to increased productivity and profitability. As industrial automation continues to advance, the importance of high-quality and dependable data communication cables will only continue to grow.