The relentless march of technology demands increasingly robust and reliable data communication infrastructure, particularly within industrial and medical sectors. These environments, often characterized by harsh conditions, electromagnetic interference, and critical operational requirements, rely heavily on specialized industrial data communication cables to support their next-generation networks. These cables are not merely conduits for data; they are essential components ensuring the integrity, speed, and security of information flow that directly impacts productivity, safety, and overall system performance.

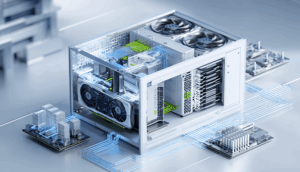

Unlike standard commercial cables, industrial data communication cables are engineered to withstand extreme temperatures, chemical exposure, physical abrasion, and constant vibration. They often incorporate shielding mechanisms, such as braided copper or foil wrapping, to minimize electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring data transmission integrity in noisy industrial environments. Moreover, these cables are designed with specific impedance characteristics to match the communication protocols employed, such as Ethernet/IP, PROFINET, or EtherCAT, preventing signal reflections and ensuring optimal data transmission speeds. The choice of conductor material, insulation, and jacket is critical in determining the cable’s overall performance and lifespan.

Within the medical field, the stakes are even higher. Data communication cables used in medical devices and diagnostic equipment must adhere to stringent regulatory requirements and biocompatibility standards. They must be resistant to sterilization processes, such as autoclaving or chemical sterilization, without compromising their electrical or mechanical properties. Moreover, the materials used must be non-toxic and hypoallergenic to minimize the risk of adverse reactions in patients. Signal integrity is paramount in medical applications, as even minor data errors can have serious consequences. Therefore, medical-grade data communication cables are rigorously tested and certified to ensure their reliability and performance in critical healthcare settings.

The evolution of industrial and medical networks towards higher bandwidth and real-time communication necessitates continuous advancements in cable technology. Fiber optic cables are increasingly being deployed in these sectors due to their immunity to EMI/RFI, high bandwidth capacity, and long transmission distances. However, copper-based cables, such as shielded twisted pair (STP) and coaxial cables, remain relevant for applications where power over Ethernet (PoE) is required or where cost-effectiveness is a primary consideration. The selection of the appropriate cable type depends on a careful evaluation of the specific application requirements, environmental conditions, and budget constraints.

Looking ahead, the integration of artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) in industrial and medical settings will further drive the demand for high-performance data communication cables. These technologies rely on massive amounts of data generated by sensors, actuators, and other connected devices, requiring robust and reliable communication infrastructure to support their real-time analysis and control. The future of industrial and medical networks hinges on the ability to seamlessly integrate these advanced technologies, and industrial data communication cables will continue to play a vital role in enabling this transformation. The development of even more resilient, high-bandwidth, and secure cabling solutions will be crucial to unlocking the full potential of next-generation industrial and medical applications.