The proliferation of Artificial Intelligence (AI) and the Internet of Medical Things (IoMT) has placed unprecedented demands on data communication infrastructure, particularly within industrial and medical environments. Robust and reliable data transmission is no longer a luxury, but a necessity for efficient operations, accurate diagnostics, and real-time decision-making. This necessitates the use of specialized industrial data communication cables designed to withstand harsh conditions and ensure seamless data flow.

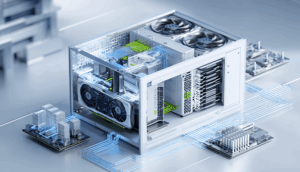

Industrial data communication cables are engineered to resist electromagnetic interference (EMI), radio frequency interference (RFI), extreme temperatures, chemical exposure, and physical abrasion – all common occurrences in industrial settings. These cables often incorporate shielding techniques, such as braided shields and foil wraps, to minimize signal degradation and maintain data integrity. Furthermore, they utilize robust jacketing materials, like polyurethane or fluoropolymers, which offer excellent resistance to chemicals, oils, and solvents. For applications requiring high flexibility, cables are designed with stranded conductors and flexible insulation materials to withstand repeated bending and flexing without compromising performance.

In the medical field, data communication cables play a critical role in connecting diagnostic equipment, patient monitoring systems, and imaging devices. The integrity of data transmitted through these cables is paramount, as even minor disruptions can have serious consequences for patient care. Medical-grade cables are therefore manufactured to meet stringent regulatory requirements, including biocompatibility and sterilization compatibility. These cables often feature antimicrobial jacketing materials to prevent the spread of infections. Furthermore, they are designed to minimize signal leakage to avoid interfering with sensitive medical equipment.

The choice of cable type depends on the specific application and the environmental conditions. Common industrial data communication cable types include Ethernet cables (Cat5e, Cat6, Cat6a), Profibus cables, Profinet cables, and Fieldbus cables. These cables are designed to support different communication protocols and data rates. For example, Ethernet cables are widely used for general-purpose networking, while Profibus and Profinet cables are commonly employed in industrial automation systems. Fiber optic cables offer advantages in terms of bandwidth and distance, making them suitable for applications requiring high-speed data transmission over long distances. However, they are typically more expensive and require specialized installation and maintenance.

Looking ahead, the demand for high-performance industrial and medical data communication cables is expected to continue to grow, driven by the increasing adoption of AI and IoMT technologies. As these technologies become more sophisticated, they will require even faster data rates, lower latency, and higher reliability. Cable manufacturers will need to innovate and develop new cable designs that can meet these evolving requirements. This includes exploring new materials, shielding techniques, and connector technologies to further enhance cable performance and durability. The future of industrial and medical data communication relies on the continuous improvement and advancement of these critical cabling components.